The not-so-complex world of t-shirt printing

Tags

Interested in joining the world's leading print on demand platform?

For decades, the trusty t-shirt has been the perfect blank canvas for memorable, iconic designs. While fashions and trends have changed, the simple combination of a quality t-shirt with a great design has remained a proven winner.

But 't-shirt printing' actually refers to dozens of different methods and techniques, each with their own pros, cons and ideal use-cases.

Let's take a look at some of them…

1. Direct to Garment (DTG)

Direct to Garment is a relatively new alternative to screen printing (more on that later). It’s also the printing method we use to produce the majority of our apparel ranges. As you might expect from the name, it involves the garment being run right through a specially made flatbed printer, on a conveyor belt. Designs are applied in one plane rather than being broken into layers.

Unlike with screen printing, pretty much anything goes in terms of colour — colours are mixed in the print-head and applied directly to garment, just the same as printing a photo. This means you can print a full spectrum of colours, without worrying about making lots of expensive screens.

DTG is much better suited for one-offs and small-order runs — in fact, it actually becomes pretty time-consuming when you're getting towards 50 or more pieces.

The finish of the design tends to feel a little different to screen printing. Screen-printed designs are smooth and soft, whereas the ink in DTG applications has a coarse, grainy feel.

One other thing to note is that, when printing on dark t-shirts, the design has to be printed on top of a white underbase.

Ideal for: colourful designs or photographs; one-offs or small runs.

Pros

- The garment is kept extremely light

- Unlimited colours

- Quicker process (and lower cost) for one-off designs and small runs

- Perfect for print on demand

Cons

- DTG printers are pretty large and take up lots of space — something to consider if you're planning to print t-shirts at home

- DTG printers are getting cheaper, but they're still pretty expensive

2. Screen printing

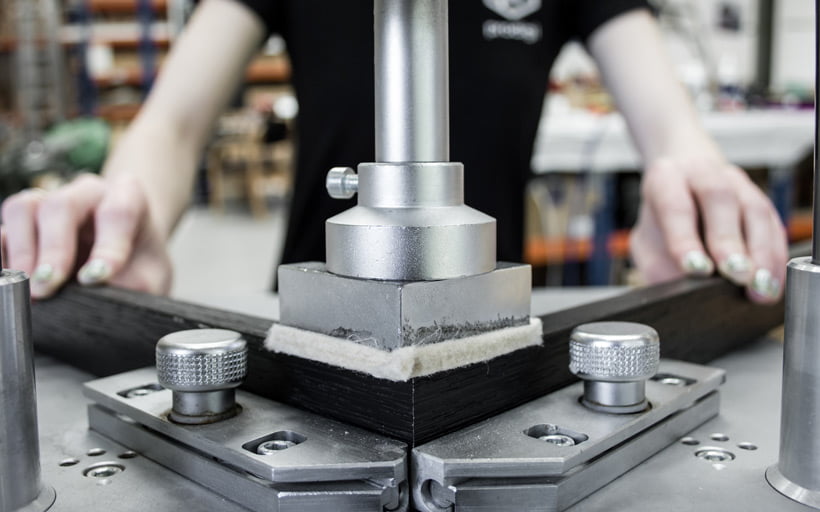

Screen printing is undoubtedly the oldest technique we'll be covering (it dates way back to the Sung Dynasty in 960–1280AD!) The broad idea is that ink or paint is filtered through a stencil or template onto the garment, as shown below.

The design is broken into different 'layers', according to the different colours used. Each colour then gets its own 'screen' — and one colour is applied at a time. This can make designs with lots of colours pretty expensive to get set up.

Since you have to build those screens, screen printing generally isn't cost effective for one-offs or small-order runs — but you'll find that the cost per garment gets significantly cheaper as quantities increase.

Ideal for large orders; designs with single/limited colours (ideally six or less).

Pros

- Excellent quality finish

- Extremely long lasting and durable

- Can be printed on cotton and poly-cotton

- Cost effective for large orders

Cons

- Not cost effective for small runs or one-offs

- Additional colours can significantly add to cost

- Colour matching can be difficult with multi-colour designs

- Can't be used for print on demand

3. Sublimation

Whereas screen printing and DTG involve applying designs onto the surface of your fabric, sublimation is where the dyes are actually penetrated into it.

This relies on perhaps the most scientifically named technique of all time: 'molecular bonding'.

In simple, less scientific words, it works like this: the design is first printed out onto sublimation transfer paper. The printer then uses a commercial heat press to transfer the design onto the garment itself. The extreme heat causes the dye on the paper to become a gas, which is then transferred into the fabric and absorbed by the fibres as it cools and solidifies. The dye actually becomes part of the makeup of the fabric.

Images courtesy of Global Orphan {:.keyimage}(

Images courtesy of Global Orphan {:.keyimage}(

With sublimation, the whole garment is printed — which makes it perfect for all-over print designs, or designs where multiple logos are required. It's a popular choice for sports team jerseys, for example, where teams have dozens of different sponsors on the sleeve, collar, chest, back and pretty much anywhere else there's a little white space! If these logos were to be printed, you'd have to pay for every application — sublimation comes at a simple, all-inclusive cost.

One important thing to note is that, generally, your print on demand items will be sublimated onto 'whole garments', rather than each panel being sublimated, then cut and sewn together. This means that some design imperfections around the seams are highly likely.

Check out our article all about sublimation to find out more.

Pros

- Unrivalled design possibilities

- Prints seam-to-seam — all over the garment

- Unlimited colour options at no extra cost

- Won't crack, peel or fade

- Ideal for print on demand

Cons

- Only suitable for garments that include polyester (100% polyester or polyester blend)

- Creasing in the seams can result in design flaws, since garments are often printed 'whole' rather than sublimating each individual panel and then sewing them together

Ideal for: small order runs; seam-to-seam designs; garments with a large number of logo or design applications.

4. Vinyl heat transfer

Heat transfer involves a printed design being transferred to the paper through heat and pressure.

Just like sublimation, the design is first printed onto specialist paper and then transferred to the garment using a heat press.

The heat triggers an adhesive on one side of the wax paper, and causes the material to stick to the fabric. The wax paper is then peeled away, and the design remains in place.

There are a few things to consider here. Firstly, the process itself can take a little while — even for an experienced printer it can take 3–5 minutes from start to finish. Because these prints are so responsive to heat, it's really important to note that prints can't be ironed.

Finer details, such as small text, can create difficulties — it often needs to be put into a background shape, as shown below.

However, it's often a popular choice because of its flexibility. It allows the transfer of full-colour photographic images. It's also much cleaner and less messy than screen printing.

Ideal for: small-order runs needing full-colour designs; bold designs without fine details/small text.

Pros

- You have the ability to print full-colour images

- Cheap for small-order runs

- Relatively quick for small order runs

- Much less messy than screen printing

Cons

- Time-consuming for larger order quantities, due to the highly manual process

- Print can be 'stiff' and inflexible

- You can't iron the print — it may melt!

- Fine details like small text often need to be 'weeded' rather than on their own. This is where you remove all the excess material from a design that's cut to shape — and, as you can imagine, it can get very fiddly when dealing with tiny items like small text

- Prints are prone to fading and cracking — not as long lasting as screen printing

- Not suited to print on demand

Conclusion

In the world of custom merchandise, 'printing' is one label that applies to many different techniques and technologies.

Hopefully, this article gave you an idea of some of those different application types — choosing the right one largely depends on your design requirements and how many garments you're printing.

The good news is, whatever your design looks like — there's a way to get it onto an awesome t-shirt and sell it to your customers!

We offer both DTG and sublimation printing on a huge range of t-shirts and other merchandise.

Interested in setting up your own print on demand t-shirt store? Check out our Shopify app.